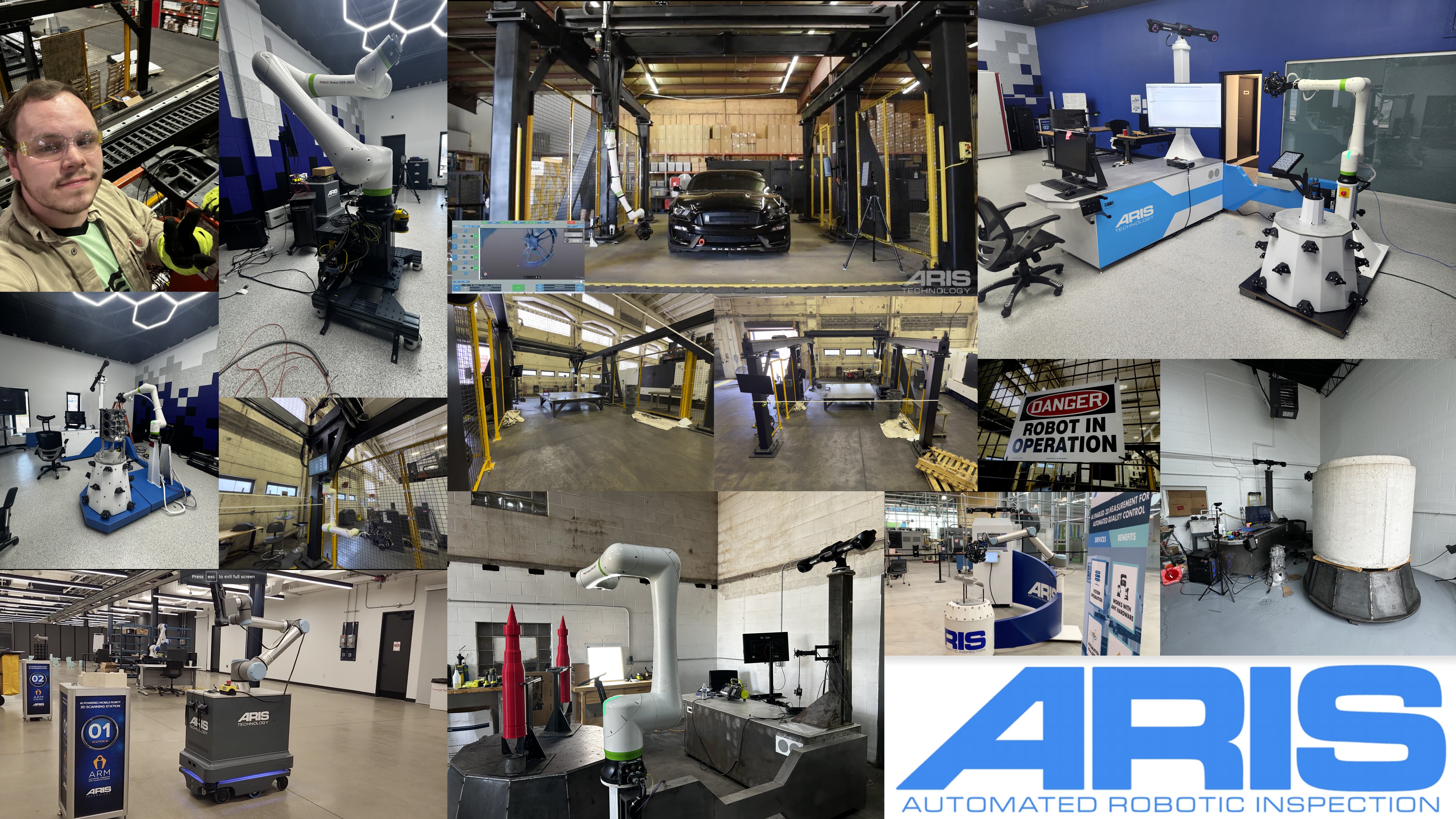

3D Scanning Robotic Cells – ARIS Technology

During my time at ARIS Technology, I played a key role in the design, development, and delivery of five unique 3D scanning robotic cells. Each system was custom-built to meet the specific needs of industries like automotive manufacturing and military facilities. These high-cost, industrial-scale machines were designed to integrate cutting-edge 3D scanning technology into production workflows, providing efficient and accurate inspection and measurement solutions.

Skills Demonstrated:

- Robotic Systems Design – Developed custom robotic systems that integrated 3D scanning technology for precision measurement and inspection.

- System Architecture and Integration – Managed the integration of multiple subsystems, including robotics, scanning hardware, and software for data processing.

- Project Management and Organization – Led project tasks throughout project lifecycle, from concept design to final delivery, ensuring timely and efficient deployment.

- Testing and Analysis – Conducted rigorous system testing and analysis to guarantee high-performance and reliability in demanding industrial environments.

Key Achievements:

- Successfully designed and deployed five unique 3D scanning robotic cells for high-profile industries, including automotive and military sectors.

- Delivered turnkey solutions that improved efficiency and accuracy in production lines and inspection processes.

- Led cross-disciplinary teams to ensure seamless integration and delivery of large-scale industrial systems.

Custom Robotics and Research – Texas Robotics

At Texas Robotics, I worked on the design, development, and integration of various custom robots, including the Cobot, BWI Bots, and Pike Robotics' oil and gas tank inspection robot. These projects involved complex design challenges and cutting-edge research in robotic systems for various industries and research purposes.

Skills Demonstrated:

- Mechanical Hardware Development – Designed and integrated custom hardware solutions for collaborative robots and autonomous systems.

- System Architecture and Integration – Managed the integration of sensors, actuators, and control systems into existing and custom-built platforms.

- Rapid Prototyping – Quickly iterated on designs, fabricating custom parts to adapt to evolving project requirements.

Key Achievements:

- Developed and integrated the Pike Robotics oil and gas tank inspection robot, contributing to hardware design, sensor integration, and field testing at an oil and gas facility in Oklahoma.

- Worked on upgrading and enhancing the Cobot platform, including the integration of a Kinova Gen3 robotic arm, which involved mechanical mounting design and electrical system rework.

- Maintained and improved the BWI Bots, ensuring their smooth operation for long-term hallway navigation and human-robot interaction research.

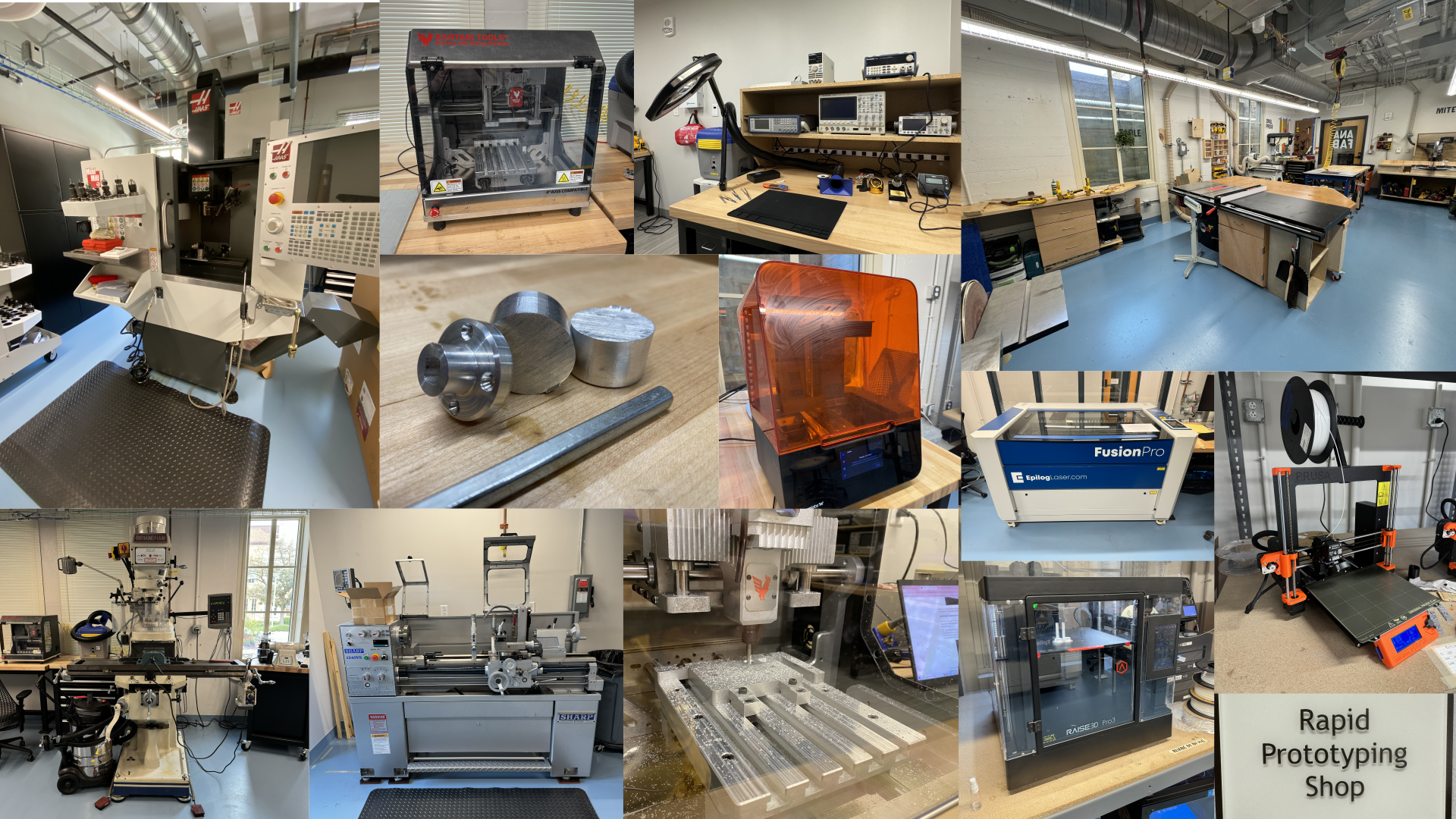

Fabrication Lab Management and Prototyping – Texas Robotics

At Texas Robotics, I managed several fabrication labs, including a Rapid Prototyping lab, a Machine Shop, and an Electronics Shop. These labs supported a wide variety of research projects, and I was responsible for ensuring that the equipment was properly maintained, users were trained, and that the spaces operated efficiently. My role also included developing custom prototypes for various robotic systems and research purposes.

Skills Demonstrated:

- Facility and Resource Management – Managed the day-to-day operations of multiple fabrication labs, ensuring safe and efficient usage by a wide range of users.

- Expertise in Manufacturing Techniques – Proficient in the use of 3D printers, laser cutters, metalworking, and woodworking machines for rapid prototyping and custom fabrication.

- Adaptability and Learning – Continuously developed and implemented new training protocols, safety measures, and operational improvements across all labs.

Key Achievements:

- Successfully managed the operation, training, and maintenance of a variety of fabrication shops, ensuring all users were properly trained and that machines were always operational.

- Implemented new safety protocols and training procedures to improve lab efficiency and user experience.

- Supported the rapid prototyping of custom robotic components for various research projects, ensuring that design and fabrication were executed with precision and speed.

Capstone Project: Pond Hopper – Water Sampling Drone

As the project manager for my senior Capstone design team at Texas A&M, I led the design and development of the Pond Hopper, a semi-autonomous water sampling drone. This drone was designed to take off and land on water, autonomously navigate to GPS coordinates, and collect water samples for mosquito larvae and environmental testing. The project combined mechanical, electrical, and software design elements, and I was responsible for overseeing all aspects of its development.

Skills Demonstrated:

- Project Management – Led a multidisciplinary team through the complete design, development, and testing process, while maintaining strong communication with project sponsors.

- Mechanical Hardware Development – Assisted in the design of the drone’s structural components, ensuring it could safely land and navigate on water.

- Rapid Prototyping – Worked with the team to fabricate and test prototypes, iterating quickly to improve functionality and performance.

Key Achievements:

- Successfully led a team to develop a fully functional water sampling drone capable of semi-autonomous operation and environmental data collection.

- Presented the project to sponsors and stakeholders, maintaining clear and effective communication throughout the development process.

- Gained hands-on experience in integrating mechanical, electrical, and software components to deliver a complex, field-tested system.